We have the best tube mills which are equipped with the latest technology and can manufacture pipes & tubes as per the industry standards

We are very consious about our quality and have a fully operational laboratory along with german spectrometer

Quality is integrated in our culture. It is not a part of the process, it is the process itself.

28 Years of experience helps us to a better understanding of requirements, demands and market trends.

We attempt to contribute towards the betterment of the world by caring about the environment.

We make every effort to meet customers’ delivery requirements by offering a number of tailored supply chain options.

Every customer’s needs are unique. We are flexible to accommodate customers’ unique requirements.

We focus all our energy, expertise and experience on Stainless Steel Pipes and tubes to help us achieve excellence.

We invest in the best machinery, testing equipment and training for our employees.

We enjoy the lowest attrition rate in the industry. Our people prefer to stay and grow with us.

The process starts with procuring raw material from the reputed producers such as Jindal ,Posco etc. After that chemical analysis,physical & mechanical inspection of coil Is done at our end then it’s rolled, welded and all the essential operations are performed such as such annealing,pickling,passivation,hydro testing ,polishing (if customer demands) and final visual inspection is done before marking and packing in order to dispatch respective customer.

Stainless Steel pipes and stainless steel are of two types- Welded and Seamless. Of these, seamless pipes and seamless tubes are considered the most ideal for expensive industries. That is because there is no worry of leakages or tears with seamless tubing.

This lack of worry is due to the seamless tube manufacturing process. Since they are not welded together using heat, they have no weak spots. They are single, consistent tubes of stainless steel. The method of producing seamless stainless piping is costlier than welding. But when it comes to transportation of fuels, medicines, chemicals, and harmful gases, it is a worthwhile investment.

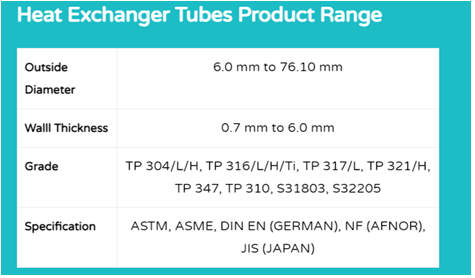

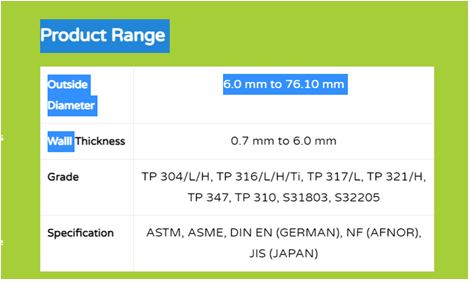

We provide SS Heat Exchanger Tubes in different OD Sizes, Wall Thickness and Grades as per customized requirements are given by our clients.

We supply Solution Annealed & Passivated Steel Tubing with assuring Quality of Closer Dimensional Tolerances and higher corrosion resistance Stainless steel Heat Exchanger Tubes.

Our Stainless Steel Heat Exchanger Tubes are being used for the heating, re-heating or cooling of fluids, air or gases in an extensive range of industries like chemical processing, oil refining and hydrocarbon processing, aerospace, and nuclear power generation.

We provide SS U-Tubes in different OD Sizes, Wall Thickness, and Grades as per customized requirements are given by our clients.

The High-Quality Stainless Steel Seamless Hollows are used for manufacturing Cold Finished Seamless U-Tubes.

We supply Solution Annealed & Passivated Steel Tubing with assuring Quality of Closer Dimensional Tolerances and higher corrosion resistance Stainless steel seamless U-Tubes.

Stainless Steel Boiler Tubes are manufactured for use in boilers and in other high heat applications. Kavery Tubing is a larger supplier of the boiler tubes in different grades, types and shapes. The most used boiler tubes are SS Seamless Boiler Tubes because they eliminate the pressure stress on the walls due to uneven internal surfaces. Our Stainless Steel Boiler Pipe products are superior and are made from materials that withstand high temperatures and are corrosion resistance to steam and hot fluids and gas.

This lack of worry is due to the seamless tube manufacturing process. Since they are not welded together using heat, they have no weak spots. They are single, consistent tubes of stainless steel. The method of producing seamless stainless piping is costlier than welding. But when it comes to transportation of fuels, medicines, chemicals, and harmful gases, it is a worthwhile investment.

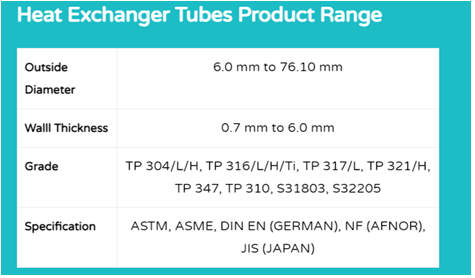

We provide SS Heat Exchanger Tubes in different OD Sizes, Wall Thickness and Grades as per customized requirements are given by our clients.

We supply Solution Annealed & Passivated Steel Tubing with assuring Quality of Closer Dimensional Tolerances and higher corrosion resistance Stainless steel Heat Exchanger Tubes.

Our Stainless Steel Heat Exchanger Tubes are being used for the heating, re-heating or cooling of fluids, air or gases in an extensive range of industries like chemical processing, oil refining and hydrocarbon processing, aerospace, and nuclear power generation.

Stainless Steel pipes and stainless steel are of two types- Welded and Seamless. Of these, seamless pipes and seamless tubes are considered the most ideal for expensive industries. That is because there is no worry of leakages or tears with seamless tubing.

This lack of worry is due to the seamless tube manufacturing process. Since they are not welded together using heat, they have no weak spots. They are single, consistent tubes of stainless steel. The method of producing seamless stainless piping is costlier than welding. But when it comes to transportation of fuels, medicines, chemicals, and harmful gases, it is a worthwhile investment.

+918511640495, +919898740495

Sedut perspiciatis unde omnis iste natrrsit voluptatem dolorem audantiun totas periam eaque ipsa quae

Sedut perspiciatis unde omnis iste natrrsit voluptatem dolorem audantiun totas periam eaque ipsa quae

Sedut perspiciatis unde omnis iste natrrsit voluptatem dolorem audantiun totas periam eaque ipsa quae

Sedut perspiciatis unde omnis iste natrrsit voluptatem dolorem audantiun totas periam eaque ipsa quae

Mobile: +91 9898740495 / 9725938866

Email : kaverytubingsolutions@gmail.com